low carbon steel hardness test|aisi steel hardness test : supplier Hardness of Low-carbon Steel – ASTM A36. Brinell hardness of low-carbon steel is approximately 120 MPa. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Acompanhantes e garotas de programa coroas em Campinas. Brasil; São Paulo; Campinas; Coroas; Descubra a arte de sedução e tenha seus desejos realizados. Campinas 37 anos R$ 200. Na região central e com novidades para vocês. Campinas 36 anos R$ 150 chat7 TD. Loirinha gaúcha safadinha e carinhosa, tenho local.

{plog:ftitle_list}

webPainel Cabeceira Cerca 90cm X 4,68 Mts Rosa 52pç C/ Dist.led. O frete grátis está sujeito ao peso, preço e distância do envio. Frete grátis no dia Compre Cabeceira 3d parcelado sem juros! Saiba mais sobre nossas incríveis ofertas e promoções em milhões de produtos.

Hardness of Low-carbon Steel – ASTM A36. Brinell hardness of low-carbon steel is approximately 120 MPa. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching.In this study, low-carbon steel was fabricated by 70% rolling with ferrite–pearlite and ferrite–martensite as starting microstructures at liquid nitrogen temperature.

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .If you need a quick, non-destructive measurement for a variety of materials in a manufacturing setting – the Rockwell hardness test is suitable. For softer materials or materials with coarse microstructures – the Brinell hardness test .The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the .The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .DEFINITION OF THE VICKERS HARDNESS TEST. The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of .Rockwell Testing Machine. This is probably the most common way of professionally and accurately checking the hardness of metals. A rounded steel ball or conical diamond tip is pushed into the metal, and the depth of the .

Low-carbon steel, also known as mild steel is now the most common form of steel because its price is relatively low while it provides material properties that are acceptable for many applications. Low-carbon steel contains .See More Brinell Testing is a fairly simple test but the most destructive type. It requires more sample prepara . Carbon Steel Angle; Stainless Steel Angle 304/304L; Channel Shop By Shape . Hardness Conversion Table for .Hardness of Low-carbon Steel – ASTM A36. Brinell hardness of low-carbon steel is approximately 120 MPa. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching.It’s most commonly used to check the hardness of steel that’s been heat treated. Here’s the process: How to Use a Rockwell Testing Machine. Pick out the penetrator. Usually soft materials like 1018 mild steel will use the Rockwell B scale, which makes use of a 1/16″ rounded steel penetrator with a 100 Kg major load.

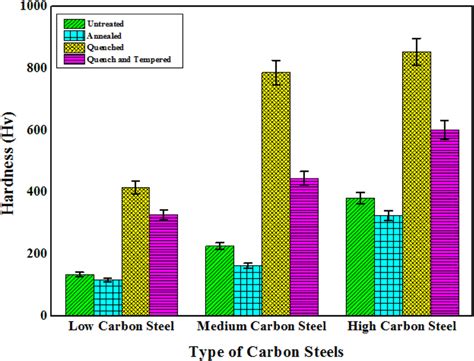

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is . It is well known that steel gains hardness with an increase in carbon content. On the other side, ductility also gets reduced with increasing carbon amount. Common chemical composition in AISI-1020-0.18% C steel is: carbon (C) = 0.20%; manganese (Mn) = 0.40%; phosphorous (P) ≤ 0.03; sulfur (S) ≤ 0.04 [1, 2]. Heat treating is a thermo .

The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.ASTM A36 Steel. ASTM A36 steel is one of the most widely used carbon structural steels, although the carbon content of A36 material is maximum 0.29%, it is considered to be the mild steel (content of carbon ≤ 0.25%).. A36 mild steel is often compared to AISI 1018, A36 carbon steel is commonly hot rolled, while 1018 steel is commonly cold rolled.. Notes: There are two .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Steel Hardness versus Strength; Brinell Vickers Rockwell Equivalent Rm; Impression Diameter (mm) Hardness HB. Hardness HV. Hardness B. Hardness C (ton f /in 2) (kg f /mm 2) (N/mm 2) 2.50: 601:Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs. Carbon steel is organized into three main categories: Low carbon steel (or mild steel) is one of the most common types of carbon steel, with a carbon content between 0.04% and 0.30%. Medium carbon steel has a carbon range of 0.31% to 0.60%, and a manganese content ranging from .060% to 1.65%.

s8 drop test review

Also hardness ranges for heat treated steel. Online shop Contact. Regional Depots. Bristol: 0117 403 1441 Exeter: 01392 790 275 Inverness: 01463 572 078 Isle of Wight: 01983 640 018 Glasgow: 0141 370 2331 Maidstone: 01622 963 030 Manchester: 0161 641 3700 .

low carbon steel hardness

Increased strength, greater hardness, and reduced formability can be imparted in these plain carbon steels as they have carbon content (0.1%0–0.25% C) compared to the lowest carbon group. They are also known as carburizing or casehardening steels by designation. . ASTM A848 is an example of an ultra-low-carbon steel (C .

ASTM A36 Mild/Low Carbon Steel. Download PDF Copy; Jul 5 2012. Topics Covered. Introduction Chemical Composition . carbon steel is defined as having up to 1.65wt% manganese, and so if there is a higher percentage than this, then that particular steel would be defined differently in terms of its grade. . What is the norm impact test for A36 . Low-carbon steel: AISI 304, ASTM A815, AISI 316L < 0.25: Ferrite, pearlite: Low hardness, high ductility, toughness, machinability and weldability: Medium-carbon steel: . One of the key characteristics of ultra .nomenclature is shown in Fig. 5.3. This is for a typical low-carbon steel specimen. Note that there are a number of definitions of the transition from elastic to plastic behavior. A few of these definitions are shown in Fig. 5.3. Oftentimes the yield point is not so well defined as for this typical steel specimen.

s8 drop test with case

Hardness of Steels. High-carbon steel has approximately 0.60 to 1.00% carbon content. Hardness is higher than the other grades but ductility decreases. Brinell hardness of high-carbon steel is approximately 200 MPa.How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . Carbon Steel: Carbon Steel | EN8 | 1.0503 | Fe . shallow case-hardened steel, cemented carbide, other materials with relatively low hardness. HRB: Ø1.588mm Hardened Steel Ball: 980.7 (100) 20-100: Soft metals, non-ferrous metals, annealed .Low-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. Mild steel has a relatively low tensile strength, but it is cheap and easy to form; surface hardness can be increased through carburizing. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for .International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.

Small amounts of phosphoric acid will show bubbling on low-chromium stainless steels, and silver nitrate will leave a black residue on magnesium (but not on aluminum). Hardness Test: The hardness test (commonly referred to as the Rockwell Hardness Test) looks at the strength of a metal against a material trying to imprint against it. Each metal .This study tested the hardness of aluminum and low-carbon steel using Rockwell hardness testing. Hardness testing measures a material's resistance to plastic deformation by indentation. The study found that low-carbon steel has a higher hardness than aluminum, as steel required greater force to deform its crystal structure. Specifically, the average Rockwell hardness of .Hence, for this test, 10 kgf was applied for 15 s to indent on the A333 Grade 6 low carbon steel specimen. The test was repeated on 5 different regions of the specimen, which include 4 edges and a midpoint of the sample. . Meanwhile, the results obtained for A333 Grade 6 low carbon steel show that the hardness value is about 166.826HV. 4.0 . ASSAB 705 steel is a machinery steel that used in several industries due to its mechanical properties, for components manufacturing. Hardening process is applied to ASSAB 705 to increase .

In Brinell hardness test, a steel ball of diameter . This was carried out by heating samples of low carbon steel to a specific temperature and then cooling them rapidly in 8 different quenching .

carbon steel hardness test

WEBA aposta fatal e a busca obsessiva por vingança foram os catalisadores que precipitaram a tragédia Falsidade No Bar Portal Zacarias. Esses eventos sombrios servem como um .

low carbon steel hardness test|aisi steel hardness test